SpeedWorx Automated Sheathing Saw

Introducing the SpeedWorx Automated Sheathing Saw. A collaboration between Safety Speed Manufacturing and ROGworx Automation. It's what you get when you take 70 years of proven manufacturing excellence and combine it with 25 years of automation expertise. We don't like to toot our own horn, but people have told us they think it's pretty cool.

What makes SpeedWorx so great?

4 Axis of Automated Movement

We automated 4 axis of movement on the SpeedWorx Saw. This provides fast and accurate part cutting.

Easy to use interface

The SpeedWorx software was created to make the saw easy to use while giving the operator the control they need to efficiently cut the parts your shop needs in the order they need them. With the "Auto-Fill" feature, the touch of a button will create an optimized cutting solution based on settings provided by the operator.

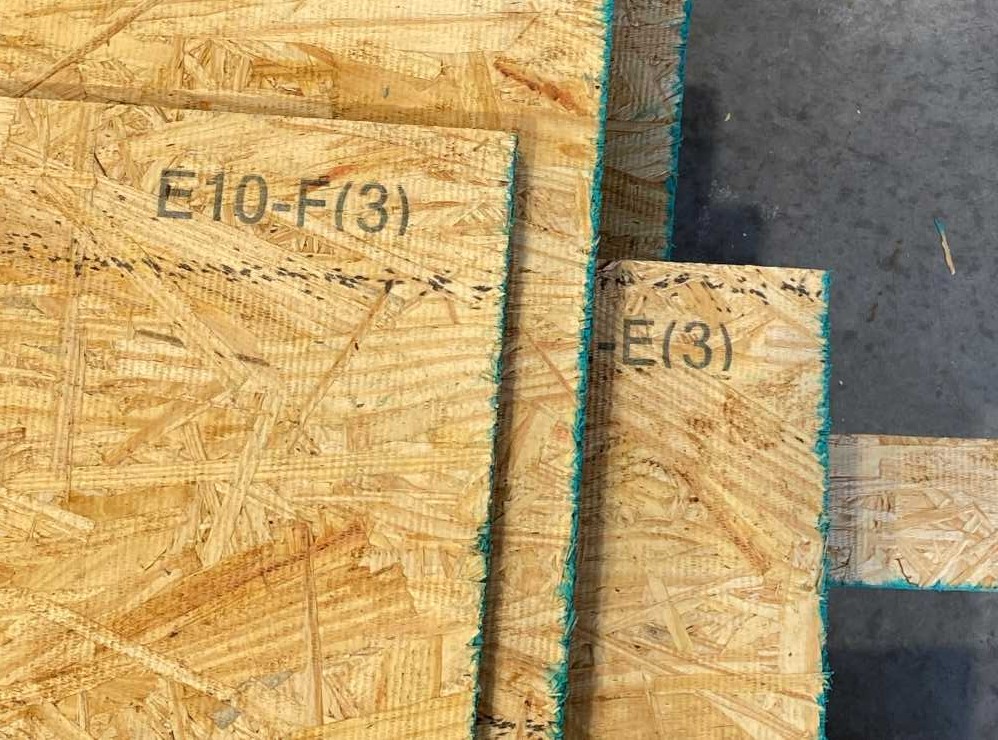

Label Printing

With the optional printer the SpeedWorx will label the parts automatically so that when they get to the line your builders know exactly where they go. No guess work. Just production.

Dust Collection

We spent considerable time designing the dust containment system for the SpeedWorx saw. The cutting chamber has two 4" ports to keep dust out of the air. The cutting chamber is enclosed to keep dust under control, even when cutting gypsum.